Robots From Thin Air: 3D-Printed, Gas-Powered, and Ready to Roll!

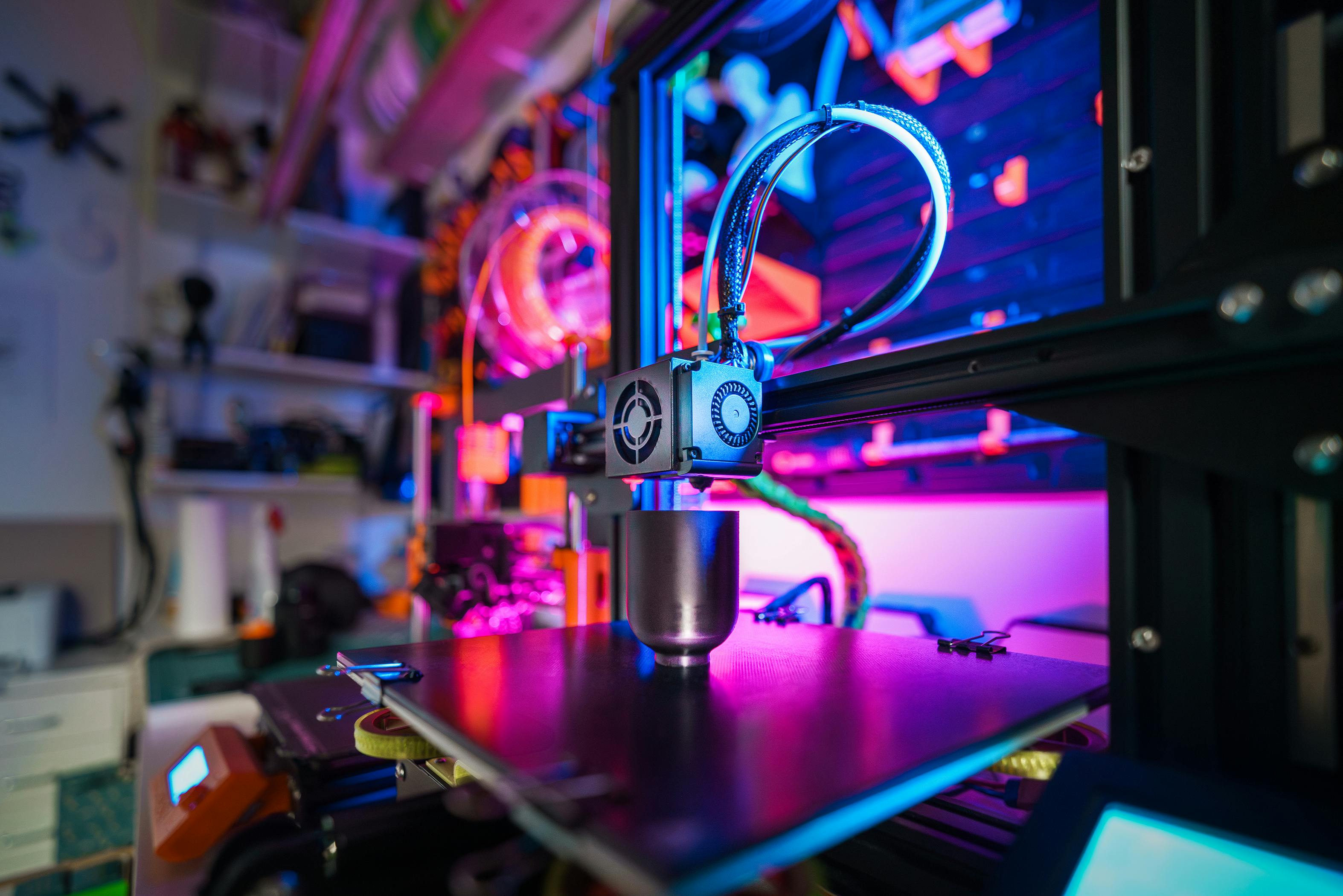

No Wires, No Worries: Meet the 3D-Printed Robot Revolution

Remember those futuristic movies where robots seemed to pop out of thin air? Well, the future is here – or at least, a fascinating glimpse of it. Forget complex circuits and painstaking assembly. We're talking about robots that can walk, powered by nothing more than a cartridge of compressed gas, and they emerge ready to roll straight from a 3D printer. Yes, you read that right. These ingenious contraptions are changing the game, and it's a story worth diving into.

The Magic Behind the Movement: How They Work

So, how does this seemingly impossible feat work? The secret lies in clever design and the power of pneumatics. These robots are built using a single material, printed in one go, and their movements are driven by carefully engineered internal chambers and channels. Here’s the breakdown:

- The Printing Process: The entire robot, including its internal mechanisms, is printed as a single unit. This eliminates the need for separate components and complex assembly.

- Pneumatic Power: Tiny channels within the robot's structure act as pathways for compressed gas (usually air or CO2). When the gas is released into specific chambers, it causes the robot's legs or other moving parts to expand and contract.

- Ingenious Design: The robot’s design is key. The arrangement of chambers, valves, and hinges dictates the walking pattern and overall movement. Engineers have to carefully consider the forces and pressures at play to achieve smooth and controlled motion.

- Simple Fuel Source: All it needs is a cartridge of compressed gas. No batteries, no charging, just a ready-to-go power source.

A Case Study: The 'Walking' 3D-Printed Robot

Let’s look at a hypothetical example to illustrate the concept. Imagine a small, four-legged robot designed for exploring rough terrain. Here's how it might function:

The 3D printer would lay down layers of a flexible, yet durable plastic. Within the robot's legs, tiny chambers are created. A central gas reservoir, also printed as part of the structure, is connected to these chambers via channels. When a valve is opened, compressed gas rushes into specific chambers, causing the leg to extend. As the gas is released, the leg retracts. By carefully timing the opening and closing of these valves, the robot can mimic a walking gait. The leg movements are sequenced in a way that allows the robot to move forward.

The Advantages: Why This Matters

The implications of these 3D-printed, gas-powered robots are significant. Here’s why:

- Simplicity and Affordability: Manufacturing is simplified because everything is printed in one go. This reduces production costs and makes the technology more accessible.

- Durability and Resilience: The lack of fragile electronics makes these robots more robust and resistant to damage, especially in harsh environments.

- Scalability and Customization: 3D printing allows for rapid prototyping and customization. Designs can be easily modified and adapted for different tasks and environments.

- Accessibility: The simplicity of the design and the absence of complex electronics make these robots easier to understand, repair, and maintain. This opens up opportunities for education and hobbyist projects.

Real-World Applications: Beyond the Lab

While still in its early stages, the potential applications of this technology are vast. Consider these examples:

- Exploration and Search and Rescue: Small, robust robots could navigate rubble, explore hazardous environments, or assist in search and rescue operations.

- Agriculture: Robots could be deployed to monitor crops, deliver supplies, or perform other tasks in agricultural settings.

- Manufacturing: Simple, adaptable robots could automate tasks on assembly lines or perform repetitive jobs.

- Education: These robots are perfect for teaching engineering principles and robotics concepts in schools and universities.

- Hobbyist Market: The ease of printing and the fun factor would make these robots popular amongst hobbyists.

Anecdote: Imagine a team of engineers tasked with designing a robot to explore a collapsed building. The traditional approach would involve designing, sourcing, and assembling numerous electronic components. With this technology, they could quickly print a fully functional robot with the right features. They could test multiple designs and iterate quickly until they achieved the desired performance.

The Challenges: What's Next?

While promising, this technology is not without its challenges:

- Precision and Control: Achieving precise movements and complex behaviors requires very fine-tuned designs and printing processes.

- Power Efficiency: Optimizing the use of compressed gas to extend operational time is crucial.

- Material Limitations: The choice of materials is currently limited. Research into new materials that are both flexible and durable is ongoing.

- Scaling Up: While small-scale robots are easily achievable, scaling up the technology for larger, more complex applications presents engineering challenges.

Actionable Takeaways: Getting Involved

The 3D-printed robot revolution is just beginning. Here's how you can get involved:

- Explore Online Resources: Search for open-source designs and tutorials to get started with your own projects.

- Experiment with 3D Printing: Learn the basics of 3D printing and experiment with different materials and printing techniques.

- Join the Community: Connect with other enthusiasts and experts through online forums and communities.

- Follow the Research: Stay updated on the latest advancements in 3D printing, pneumatics, and robotics.

- Consider Education: Look into engineering or robotics programs to delve deeper into the concepts.

Conclusion: A Glimpse into the Future

3D-printed, gas-powered robots represent a significant leap in robotics, showing us the potential of simplicity, affordability, and adaptability. By eliminating the need for complex electronics, these robots open up exciting possibilities for a wide range of applications. While challenges remain, the future of robotics is looking bright, and these ingenious devices are paving the way for a more accessible and innovative world.

This post was published as part of my automated content series.